If you own or operate machinery that uses valves, it can be a good idea to invest in valve lockouts for the safety of people around the machinery as well as the function of the machinery itself. Sometimes called a valve lock, the valve lockout can come in many different shapes and sizes depending on the application of the valve in question.

What is a Valve Lockout?

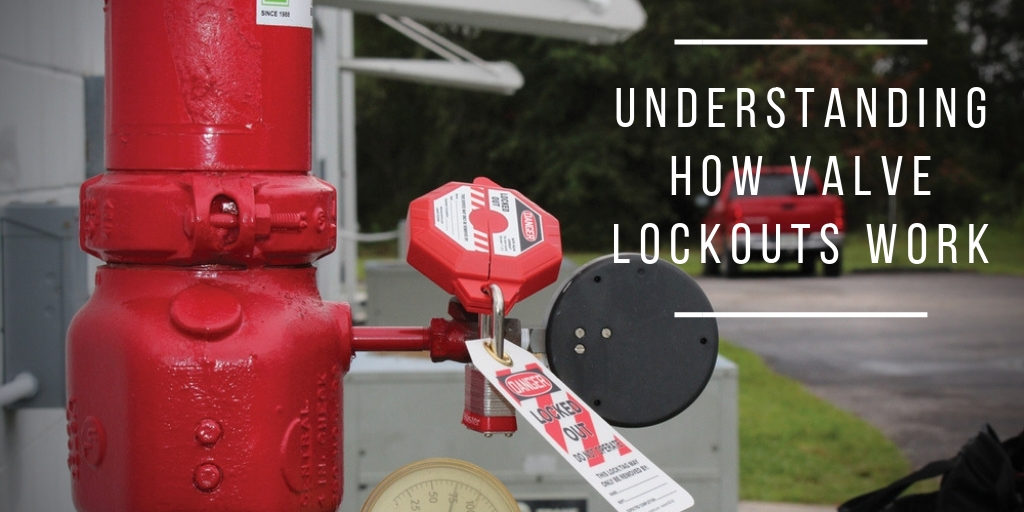

Simply put, a valve lockout is a device made to keep a valve in place while maintenance is being done. It is held tightly by padlocks or sometimes hasps to keep it from shifting.

What Kinds of Valve Lockouts Exist?

If there is a valve, there is likely a valve lockout to go with it. Valve lockouts range from pressurized gas valve lockouts, seal tight ball valve lockouts, wedge style ball valve lockouts, adjustable ball valve lockouts and rotating gate ball valve lockouts. To figure out what kind of valve lockout you need, examine your valve and consult any relevant operating instructions.

How Big are Valve Lockouts?

The answer can depend on the size of the valve. Some valve lockouts fit over the entire valve, while other valve lockouts are designed to lock over only an essential portion of the valve. Particular models may feature specific clamps to hold a lever in place, while others use a sturdy wedge to slide between a lever and handle and immobilize their movements.

How Important are Valve Lockouts?

Many safety officials would agree that valve lockouts are very important in preventing accidents and injuries. For the well-being of you and your employees, consider investing in valve lockout mechanisms. They are also beneficial in preventing expensive machinery breakdowns that could require time-consuming service work. If you value safety and productivity, then valve lockouts can be an important part of your operation.